STS Capper Gear and Bearings

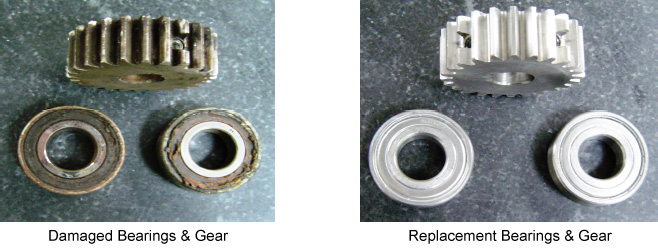

The STS Cappers are the units that tighten and secure the Blackhawk SuperQuad caps on current SuperQuad bottles. The virtually maintenance free units are made to withstand the harsh conditions at the dairies. Over years of use, some of the key components wear out over time. The key components on the STS Cappers are the gears and stainless steel bearings. If the stainless steel bearings or gears are damaged, this could be a major failure in production at the plant. What we have found is these units last around three years before they need to be refurbished. Depending on how these units are used in production, some units will last longer and some shorter. The first component is the gear we will look review.

The STS Capper 316 stainless steel gear meshes up to the bull gear on the capper turret. This key component rotates the universal drive shaft which ultimately tightens the cap on the bottle. Over years of use, the gear teeth will wear. As the gear teeth wear, they may not engage to the bull gear in the correct manor. A key indicator may be seen if the drive shaft does not rotate from time to time on one section on the filler. This is a very rare occurrence but can happen. If the teeth are worn, it would be time to replace the units. If the unit is out of place and not engaged to the bull gear, loosen the units and push the unit in to engage the bull gear. This will allow the STS Cappers to continue to work. Another component that needs to be checked is the stainless steel bearings.

The stainless steel bearings keep the universal drive shaft in place. These two components are located in the top and bottom plate. These components allow for a smooth rotation in tightening the caps down. The bearings begin to lose their working function around three years depending on how the STS Cappers are used. The bearings begin to squeak and the inside FDA grease dissipates due to washing and spraying the units down. Depending on how much vertical force is applied to the bottle, sometimes, the top cover to the bearings will disengage leaving the bearings internal components exposed. To avoid this scenario, after two years a Blackhawk representative can check the units when they are at the plant. If they recommend “Swapping Out” the units, it would be considered a good time to replace the units on that filler before a major failure occurs which could result in down time and lost production.

Get Notified Of New Posts