Bull Gear in Capper Turret

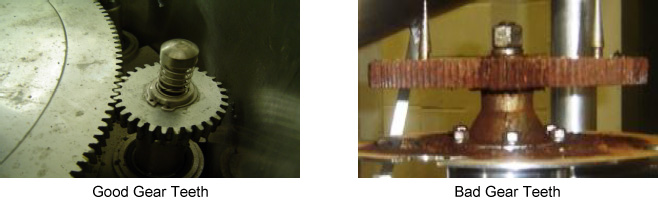

The Bull Gear is the integral component that allows the STS Cappers to perform in tightening Blackhawk’s SuperQuad cap. The gear is in an enclosure, located on the capping turret and cannot be seen. This unit is sometimes neglected and will create a major problem in production if preventative maintenance is not maintained. The major issues with the bull gear, is rust build up and broken teeth.

Rust build up on the bull gear begins when cleaning the filler bowl and capping turret. The guard plate that sits below the bull gear has openings where water can penetrate and attach the bull gear. If the gear is not properly maintained by using an FDA approved lubricant, the bull gear teeth will begin to rust. This scenario can take years to before anyone even looks under the capping turret to see what may be happening. Instructions on preventative maintenance should be either in the manual provided by the filler manufacturer or a phone call to the engineering department to walk through the steps on the preventative maintenance. If at some point there is rust build up, a wire brush or a wire wheel can be used to clean the bull gear. This will allow the appropriate rotation for the gears on the STS Cappers to run with out issue. The second issue is broken bull gear teeth.

Bull gear teeth can be broken if preventative maintenance is not used at all. This occurs when no FDA lubricant is virtually never put on and rust builds and begins to flake off, leaving smaller sections and begins chipping the bull gear teeth. As the bull gear teeth begin to erode the engagement between the STS Capper gears and bull gear will decrease. This engagement will actually break teeth off of the bull gear creating an area where no engagement will occur. This issue can result in loose caps not sealing the bottle and generate product that will leak out in the field. This could be a costly problem if this is not caught in time and return product is returned and the price of a new bull gear.

The last major item is the bull gear bearing. This bearing does not have an indefinite life. The bearing needs to be looked at periodically to ensure it is working correctly. This issue will need to be resolved with the filler manufacture with assistance in replacing this key component.

Get Notified Of New Posts